Choosing the ideal roofing material can be daunting, but for many projects, single-ply roof membrane systems offer a solution that combines durability with cost-efficiency. Whether you’re evaluating PVC, TPO, or EPDM options, these membranes are lauded for their ease of installation and ability to protect your structure from the elements. This guide will compare the top single-ply materials, discuss what to consider when selecting them, and examine their long-term benefits—cutting through the complexity to help you make a well-informed decision for your roofing needs.

Key Takeaways

- Single-ply roofing systems, characterized by their simplicity and durability, are popular for commercial and industrial buildings. Various varieties, such as TPO, PVC, and EPDM, offer unique benefits and applications.

- Choosing the right single-ply membrane involves considering factors like the building’s design, structure, location, and environmental exposure, balancing cost with performance and compliance with building standards.

- Regular maintenance and professional installation are crucial for maximizing the lifespan and performance of single-ply roofing systems, which, with proper care, maintenance, and potential restoration techniques, can last up to 30 years.

Understanding Single Ply Roofing Systems

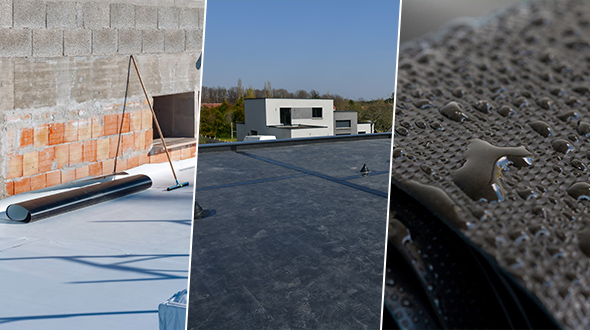

In the vast world of roofing systems, single-ply roofing systems occupy a special place. These systems consist of a single-ply roofing membrane, a single layer of waterproofing material that stands guard between the structure and external elements. Made from materials such as PVC, TPO, or EPDM, these membranes are the unsung heroes of commercial and industrial buildings, protecting them from the wrath of the elements while offering a touch of aesthetic appeal.

The popularity of single-ply roofing systems stems from their lightweight design, ease of installation, and satisfactory service life. They are well suited for commercial and industrial applications, adapting to varying conditions and performance demands with flexible color options. Certain single-ply membranes even provide superior puncture resistance and are suitable in chemically aggressive environments, representing continuous improvements in TPO composition and design.

Thermoplastic vs. Thermoset Membranes

In the realm of single-ply roofing membranes, two categories reign supreme: thermoplastic and thermoset. On the one hand, we have TPO membranes made from synthetic polymers and reinforcing scrim. TPO is the popular kid in the world of commercial roofing, thanks to its cost-effectiveness and ability to weld its seams. Its reflective surface is resistant to UV radiation and wear, standing up to the test of time and weather with remarkable resilience.

On the other hand, we have EPDM, a thermoset membrane composed of ethylene and propylene. This membrane is a testament to the wonders of flexibility, affordability, and performance in a range of temperatures. However, each of these membranes has its unique advantages and disadvantages, which is why understanding them is crucial for making a well-informed decision.

Common Applications

Single-ply roofing systems are the chameleons of the commercial roofing systems world. Due to their versatility, they adapt to various types of installations. Whether it’s a small commercial installation where the lightweight and durable PVC membrane is the perfect fit or a low-slope roof that demands durability and reliability, single-ply roofing systems rise to the occasion.

Not just that, these systems also find extensive use in industrial facilities, accommodating the unique demands of such environments with ease.

Key Factors to Consider When Choosing a Single Ply Roof Membrane

The world of single-ply roofing systems is diverse, and choosing the right membrane isn’t always straightforward. It’s not just about selecting a membrane but choosing a solution that fits your unique needs. Factors to consider include:

- The type of structure

- Substrate material

- Location

- Anticipated loads and stresses

- The client’s risk tolerance related to the building’s use and geotechnical conditions

Taking these factors into account will help you make an informed decision.

To ensure safety and performance, the chosen single-ply membrane must comply with building codes and industry standards, including criteria for fire, wind, and impact resistance. Let’s not forget the importance of the manufacturer’s reputation and the support they offer, such as warranty programs. After all, a roofing membrane is an investment, and it’s essential to balance cost considerations, including initial investment and desired performance, with the overall budget for the roofing project.

Climate and Environmental Conditions

Climate and environmental conditions are crucial in choosing a single-ply roofing system. For instance, EPDM is an exemplary single-ply roofing material that can endure extreme temperatures from -20°F up to 200°F, proving its mettle in cold climates with its heat-absorbing black surface that helps melt snow.

However, the battle with the elements is not always about temperature. UV radiation can severely degrade single-ply membranes by attacking adhesives, leading to weakened seams and potential leaks. To counter this, white single-ply membranes, with their high reflectivity, come to the rescue by reducing cooling costs and keeping buildings cooler in warm climates.

Some single-ply membranes are chosen for their chemical resistance and durability against chemical exposures, which are perfect for restaurants and the like.

Building Design and Structure

A building’s design and structure are like a puzzle, and the single-ply roofing system, which includes membrane roofing systems, must fit into it perfectly. These membranes can adapt to unique roof designs and withstand building movement due to thermal expansion and contraction. This adaptability is crucial in ensuring the membrane’s longevity and effectiveness while keeping the roof from leaking.

Oftentimes, a cover board may be necessary to provide optimal performance of the roof’s insulation, adding to the roof structure’s load-bearing capacity. This insulation layer serves as a protective shield for the insulation, enhancing its effectiveness and ensuring the roofing system’s overall performance.

Budget and Cost Efficiency

While single-ply roofing systems offer many benefits, it’s essential to consider your budget and the overall cost efficiency of your chosen system. Installation requirements, roofing contractor expertise, and special considerations such as building design and environmental factors are major contributors to the initial cost.

Analyzing the initial cost in conjunction with long-term maintenance needs is essential for understanding the overall cost efficiency of single-ply roofing materials. For instance, TPO roofing, known for its high puncture resistance, fire resistance, and strong seams, offers unique benefits and reduces maintenance costs over time, making it a perfect option for many properties.

Advantages and Disadvantages of Single Ply Roofing Materials

Like all things, single-ply roofing materials have their advantages and disadvantages. On the one hand, they are sought after for their sustainable attributes, including:

- High recycled content

- Low VOC emissions

- Recyclability

- Energy-efficient properties that reduce heating and cooling costs

On the other hand, certain materials, such as EPDM membranes, are less durable compared to TPO and PVC options. However, TPO membrane has not been on the market as long as EPDM, indicating a shorter track record.

To help you navigate which is best for your situation, below are the unique qualities, advantages, and disadvantages of the three single-ply membranes.

TPO Membranes

TPO roofing systems are a shining star in the world of single-ply roofing systems. They’re a three-layered membrane that incorporates a TPO polymer base, a polyester-reinforced scrim, and a TPO compounded top ply. This offers a level of flexibility that’s compatible with different roof types and capable of withstanding building movement.

The advantages of TPO roofing are numerous:

- High solar reflectivity, leading to greater energy efficiency

- UV resistance, prolonging roof life

- Resistance to wear

- Seams welded with hot air, providing superior leak protection

- Aesthetic versatility, available in multiple colors to enhance various building designs

However, the quality of seam welding can be a drawback if not properly executed, indicating the necessity of expert installation to mitigate potential seam issues.

EPDM Membranes

EPDM membranes have their own set of benefits and limitations. Here are some of the benefits:

- Durability

- They are effective in cold climates due to their heat-absorbing black surface, which helps melt snow.

- Reliable choice for areas experiencing harsh winters

However, every rose has its thorns. EPDM roofing systems can be more susceptible to punctures than some other single-ply materials. They can also incur damage from regular foot traffic and wind-driven debris, which are potential disadvantages. Standard methods of installing EPDM include full adhesion, mechanical attachment, or ballasting, with seams sealed by gluing or taping. This highlights the importance of proper installation and maintenance to ensure the longevity and effectiveness of EPDM roofs.

PVC Membranes

Last but not least, PVC membranes offer their own advantages. These membranes are highly resistant to chemicals and animal fats, making them suitable for environments like restaurants. Their chemical resistance properties enhance their durability, making them a reliable choice for challenging environments.

However, despite their advantages, PVC roofing material has a higher price point than other single-ply roofing options. This makes it a more significant investment, but its durability and chemical resistance often justify the cost in the long run.

Installation Methods for Single Ply Roofing Systems

When it comes to installing single-ply roofing systems, there are several methods to choose from. These include fully adhered, mechanically attached, and ballasted methods. Each method has its unique advantages and challenges. Single-ply roofing sheets are ideally designed for low-slope roofs and feature fewer seams compared to other roofing systems, which allows for a more straightforward installation process.

However, challenges in installing single-ply roofing include:

- The need for proper installation techniques to ensure seam integrity

- The material becomes less pliable in cold weather

- Potential issues such as blisters and wrinkles

- Extended curing times for water-based adhesives

Fully Adhered

The fully adhered installation method involves the following:

- Unfolding the membrane

- Applying adhesive to both the underside of the membrane and the insulation or coverboard

- Pressing the membrane into place once the adhesive is tacky

Single-ply membranes are directly glued to the insulation boards in fully adhered systems. These insulation boards are then secured to the roof deck below.

Adhesion of the single-ply membranes to the roof substrate can be achieved using different types of adhesives, such as water-based contact adhesives, moisture-cure urethane adhesives, or solvent-based adhesives. Specific single-ply roofing accessories are employed to ensure water tightness around areas with complex geometry, like pipes and edge transitions.

Mechanically Attached

Mechanically attached single-ply systems are another option. In these systems, the membrane is screwed into the metal decking. The seams of mechanically attached systems are fused using heat or adhesive.

This is the most common type of single-ply installation known for its ease of installation and cost-effectiveness.

Ballasted

Ballasted membranes simplify the installation process. These membranes are not anchored to the decking material; they are held in place by a heavy layer of gravel. This loose-laid nature simplifies the installation process, making them a preferred choice for specific applications.

Maximizing the Performance of Your Single Ply Roof Membrane

The performance of a single-ply roofing system is not just about the type of membrane used or the installation method chosen. It’s also about proper maintenance and timely repairs. With the right care, TPO roofs can have a potential lifespan of 20-30 years, and PVC roofing membranes can last up to 30 years or more. These systems generally require fewer repairs than others, contributing to their longer service life.

Regularly removing debris like leaves and twigs from the roof can prevent issues such as leaks and mold growth, which are detrimental to the roofing membrane’s condition.

Proper Installation

Working with seasoned professionals who have years of experience minimizes installation errors. Experienced contractors possess the critical skill set necessary for high-quality roofing installation. They are up-to-date with industry best practices and are evaluated for their competency, thus ensuring the quality of the installation. Moreover, professional roofing contractors offer warranties that cover materials and labor, offering protection against workmanship errors and material defects.

Choosing roofing contractors with a positive reputation in the local community can provide additional assurance of reliable and trusted work. Professional roofers adhere to the best safety practices, which is crucial as roofing installments involve working at heights and managing hazardous materials. Engaging a professional roofing service in the commercial roofing market can lead to savings by having proper insurance coverage and compliance with building codes, thereby mitigating the risk of unnecessary future costs from accidents or non-compliance.

Regular Maintenance

Proper maintenance is key to the longevity of single-ply roofing systems. Routine inspections, ideally conducted twice annually, can help detect and fix potential issues before they escalate into major problems.

Routine maintenance tasks for single-ply roofing membranes include:

- Checking drainage channels

- Ensuring the integrity of waterproofing

- Inspecting flashing and expansion joints

- Assessing roof fasteners

Establishing a semi-annual maintenance plan is key to extending the life of single-ply roofing membranes. To mitigate common issues such as ponding water and UV degradation, it is important to maintain proper drainage, conduct regular inspections, and consider the application of protective coatings.

Repair and Restoration Options

Repairs on single-ply roofing should be conducted promptly and with the correct materials to ensure the membrane’s long-term integrity. But beyond repairs, single-ply roofing systems can also be restored using fluid-applied roof restorations such as Spray Polyurethane Foam (SPF) or a roof coating system. This can significantly extend the systems’ life.

Silicone coatings and acrylic elastomeric coatings are other options for restoring single-ply roofing systems. These restorative coatings not only extend the life of the roofing systems but also enhance their performance. So, whether it’s a minor repair or a major restoration, the goal is to maximize the performance and extend the life of your single-ply roofing system.

Single Ply Roof Summary

In conclusion, single-ply roofing systems offer a versatile, durable, cost-effective solution for commercial and industrial applications. They can adapt to diverse environmental conditions and building designs, making them a popular choice in the roofing industry. However, choosing the right membrane, ensuring proper installation, conducting regular maintenance, and exploring repair and restoration options are crucial to maximizing the performance and extending the life of these roofing systems. With the proper care and maintenance, a single-ply roofing system can prove to be a long-lasting and reliable investment for your building.

Single Ply Roofing Frequently Asked Questions

What are single-ply roofing systems?

Single-ply roofing systems are composed of a single layer of waterproofing membrane, typically made of PVC, TPO, or EPDM, providing protection against external elements.

What’s the difference between thermoplastic and thermoset membranes?

The main difference between thermoplastic and thermoset membranes is that thermoplastic membranes offer a reflective surface resistant to UV radiation and wear, while thermoset membranes offer flexibility, affordability, and performance in a range of temperatures.

What factors should I consider when choosing a single-ply roof membrane?

When choosing a single-ply roof membrane, consider project-specific factors, building codes, manufacturer reputation, cost, environmental conditions, building design and structure, and budget and cost efficiency. These factors will help you make an informed decision.

What are the installation methods for single-ply roofing systems?

You can install single-ply roofing systems using fully adhered, mechanically attached, or ballasted methods. Each method has its own advantages and considerations.

How can I maximize the performance of my single-ply roof membrane?

To maximize the performance of your single-ply roof membrane, focus on proper installation, regular maintenance, and exploring repair and restoration options. Working with experienced professionals and conducting routine inspections can help prolong the life of your roofing system.

(404) 220-9288

The post Single Ply Roof Membrane System Explained appeared first on atlantacommercialroofingcontractors.com